Introduction

What does RRR mean?

RRR are reinforced structures that include embankments, retaining walls,

water-front structures, bridge abutments, bridge systems etc. constructed for railways,

highways and others.

RRR reinforced soil structures comprises four sub-systems, A to D:

| Category | Structure type |

|---|---|

| RRR-A | Reinforced-soil bridge abutments & bridge systems |

| RRR-B | Geosynthetic-Reinforced Soil (GRS) retaining walls |

| RRR-C | Nail-Reinforced Soil (NRS) retaining walls |

| RRR-D | GRS structures to prevent water-front disasters |

| OHTERS | GRS Box Culvert / GRS Tunnel Entrance |

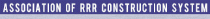

RRR-AReinforced-soil bridge abutments & bridge systems

・GRS Bridge Abutments, using bearings to support a simple girder.

・GRS Integral Bridges and NRS Integral Bridges structurally integrating the girder respectively, to the top of FHR facing connected to GR backfill, and to the top of RC abutment connected to nailed backfill.

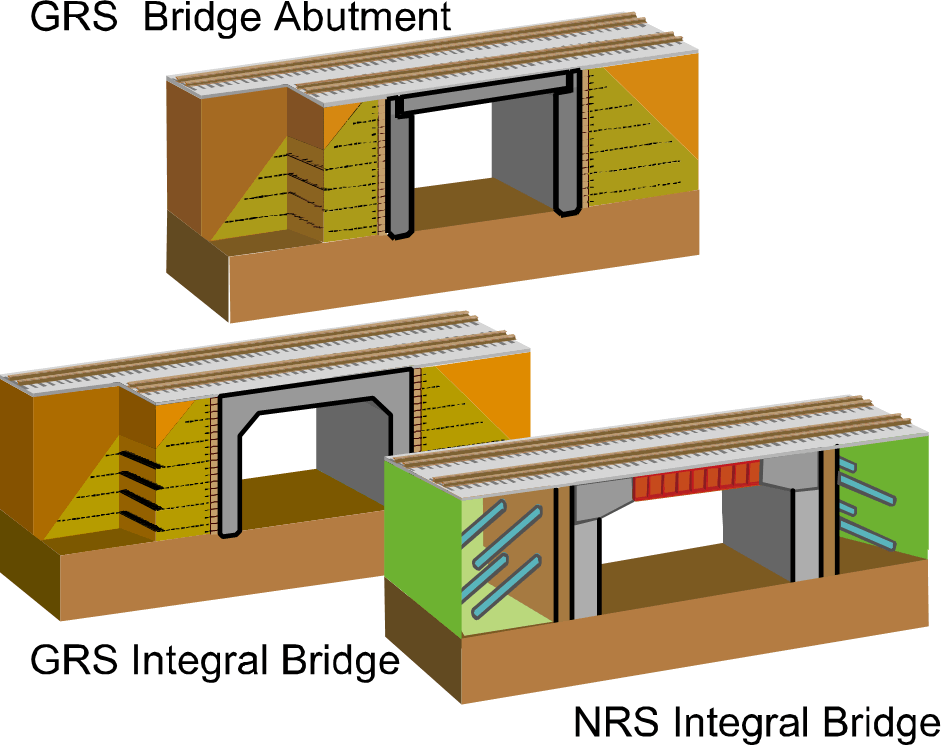

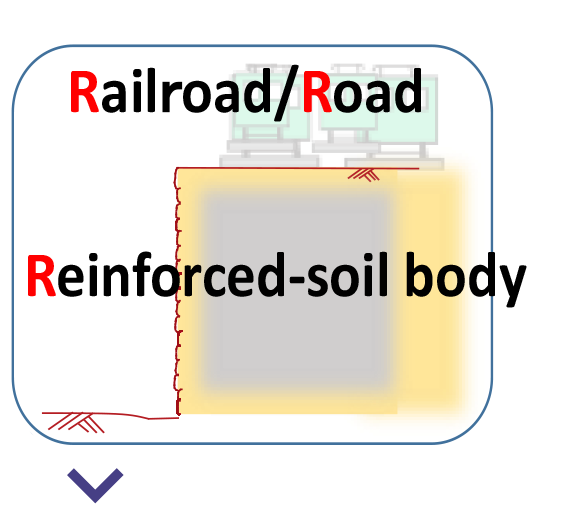

RRR-BGeosynthetic-Reinforced Soil (GRS) retaining walls

・GRS retaining walls (RWs) with full-height rigid (FHR) facing

・GRS RWs with FHR facing can support railway tracks or roads arranged close to the wall face. They can also support continuous RC slab railway tracks and external loads acting on, or close to, the facing.

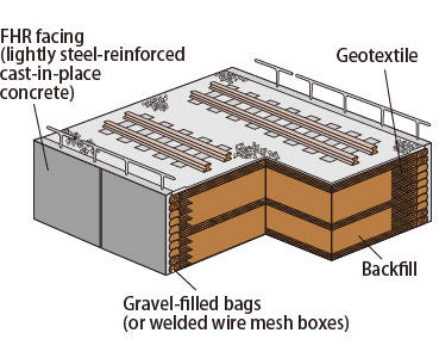

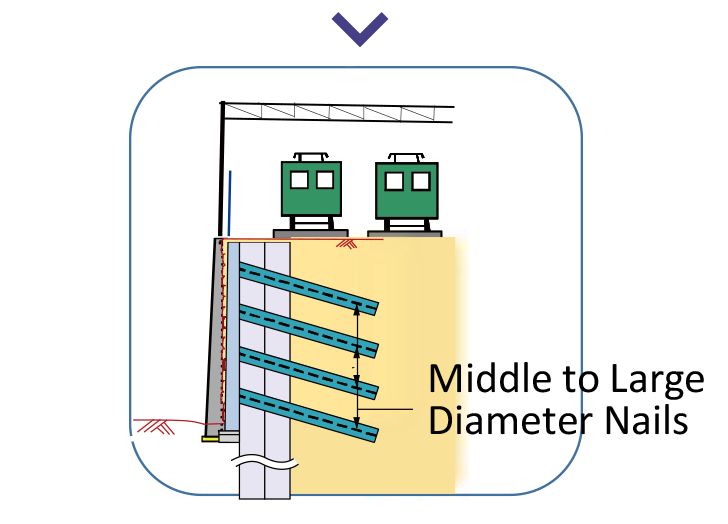

RRR-CNail-Reinforced Soil (NRS) retaining walls

・Natural slopes and embankment slopes are cut to vertical walls by reinforcing slopes with medium to large diameter nails using full-height rigid facing.

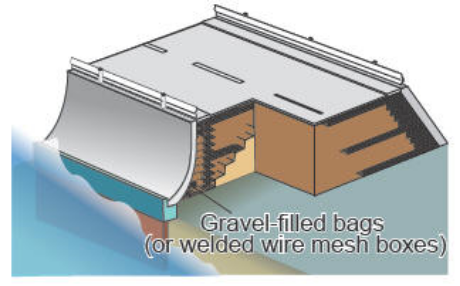

RRR-DGRS structures to prevent water-front disasters

・Water-front GRS structures to prevent and mitigate disasters caused by scouring, erosion and overtopping flow by flood, storm and tsunami.

Others

Brief history

Patent No.1870191 for "Embankment stabilization method by soil-reinforcing and structures constructed by this method"

BASIC PRINCIPLES

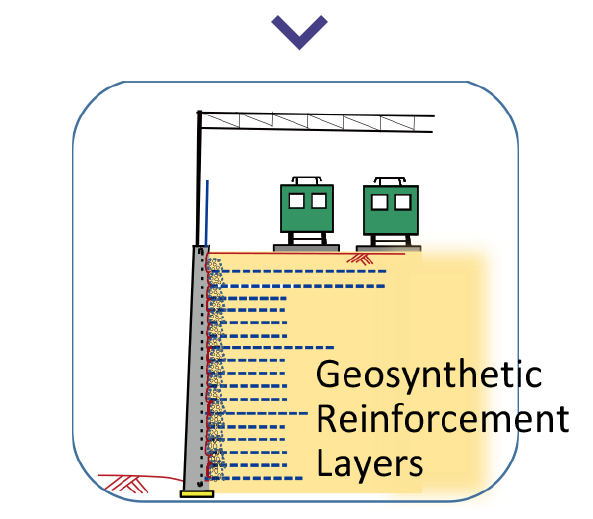

RRR structures are hybrid structures integrating a rigid facing and a reinforced soil body. The RRR structures can exhibit outstanding performance by combining advantageous features of rigid facing and reinforced soil body.

The basic principles of the RRR construction system are shown below:

Reinforced Soil Body

Staged Construction※ and Firm Connection between Rigid Facing and Reinforcements

RRR-A,B & D

RRR-A,B & D

a rigid facing and a reinforced soil body

(in particular, against high seismic loads)

or

embankment slopes

RRR-C

RRR-C